3D printing is being hailed as the future of manufacturing yet it's been around, technically, since 1981. Now Carbon3D is here to shake up the industry with its revolutionary new printer that's faster, more accurate and higher resolution.

The Carbon3D printer was announced at a TED event on Monday. The printing method was unveiled as Continuous Liquid Interface Production (CLIP) which effectively grows objects rather than printing them.

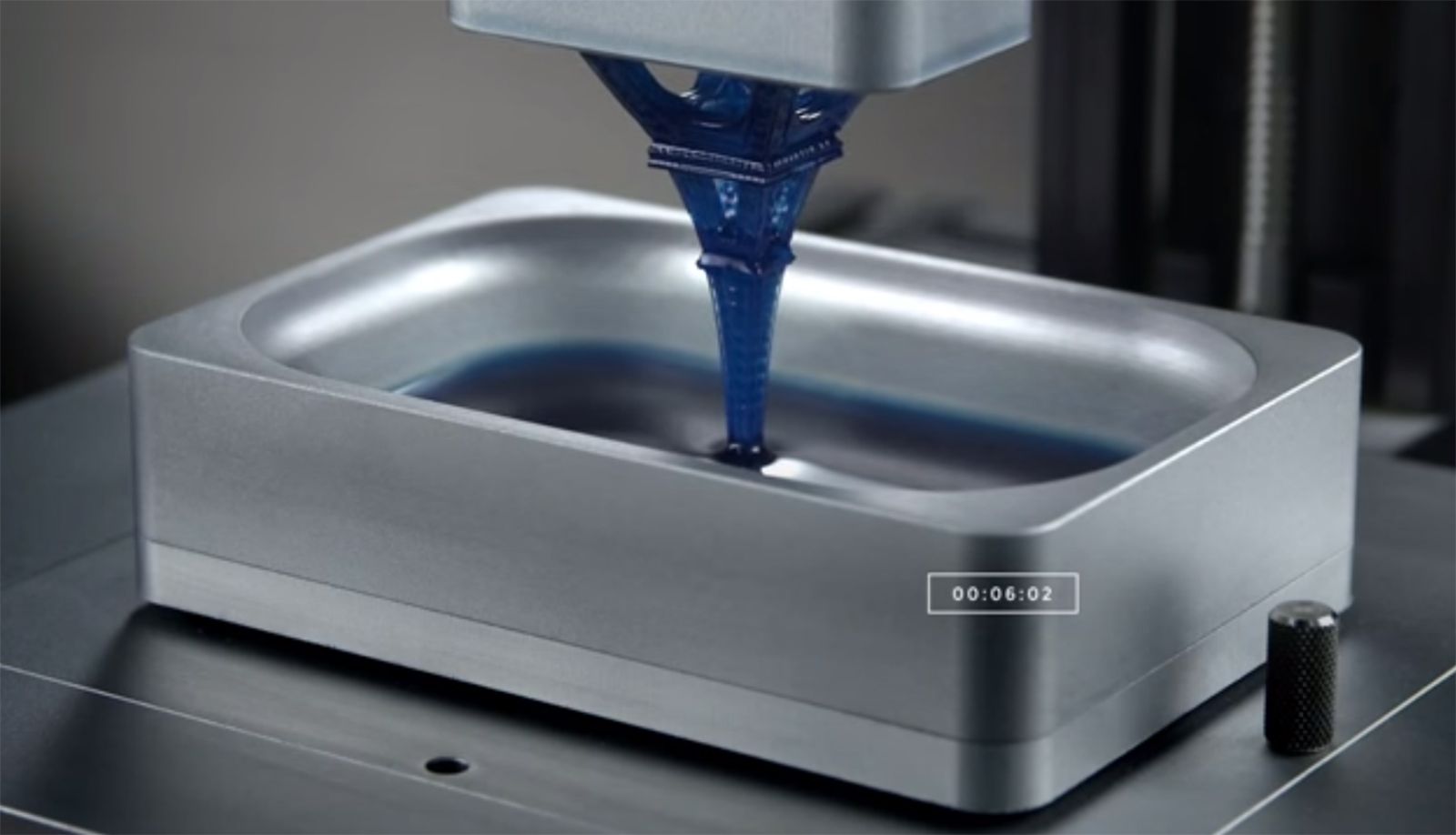

The CLIP method works in a liquid state using light and oxygen to create solid objects. The result, as can be seen in the video below, is object creation at a rate of thousands of millimetres per hour. This Eiffel Tower model took just 6-minutes.

So what does this mean for the future? Now doctors can create specific tools to fit inside parts of individuals on the operating table right there as they need them. For example a person-specific stent could be made to hold open arteries as and when needed.

This also means that manufacturing can speed up even faster.

While partners were not announced it was said that Carbon3D is perfect for creating running shoes, dental implants, parts that take the rattle out of cars and more.

READ: 3D printing: Everything you need to know and when it'll be affordable