Six patents have been published this month that reveal Dyson is working on a near-silent hairdryer.

The British firm has already reinvented the vacuum cleaner and hand-dryers, setting its sights on hairdryers seems like the next logical move.

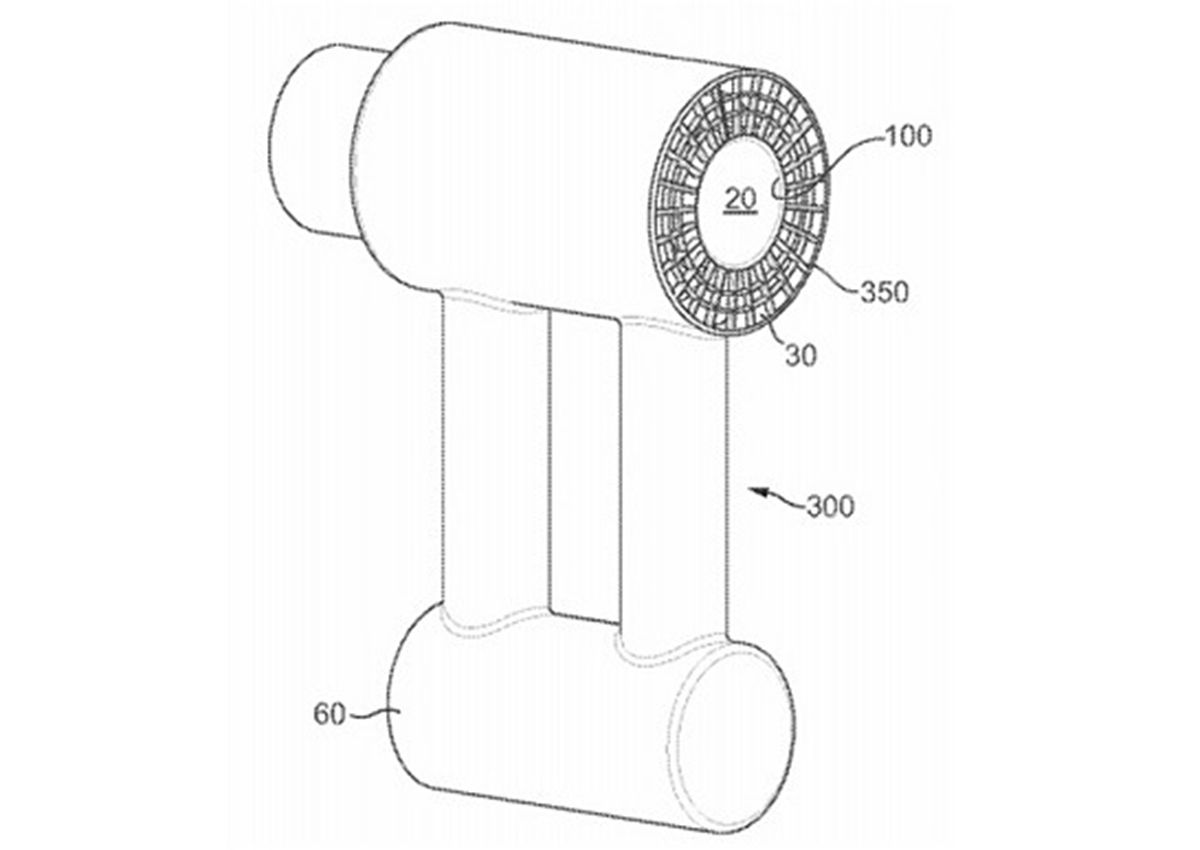

Current hair dryers are noisy creatures, generally producing in excess of 70 decibels. Dyson plans to use a network of ducts and tubes in the handle of its device to increase air flow while using a smaller fan. It will also be using materials for soundproofing and vibration reduction.

The patents call it, "hand-held blower with heater". Perhaps it will be more than just a hairdryer - it could be optimised for drying wet clothes, for example.

Dyson's current DC59 vacuum cleaner is already handheld showing the company is on the right path with a small motor and battery in mass production right now. Perhaps this down-sizing of components could also help in the progress toward Dyson's DC06 robot vacuum cleaner coming to market too.

The patent says that air is drawn into the device through a filter to remove dust and other objects, a small fan housed in the handle draws some of the air down through a looped path before injected it back into the main flow. Dyson says using a looped or zigzagged path for the air to travel through can reduce the noise produced by the appliance.

A small fan in the base of the handle would draw half of the air down into ducts that run through the handle and around the main tube. This air would pass over a heating element before being injected back into the main flow close to the nozzle, creating a jet of hot air.

Dyson says: "The provision of a hairdryer in which the fan assembly only processes part of the flow is advantageous for a number of reasons. As less fluid is drawn in, the motor of the fan assembly can be smaller and lighter in weight, the noise produced by the fan assembly can be reduced as there is less flow thorough the fan, this can result in a smaller and or more compact hairdryer which uses less power.

"The noise of the hairdryer is reduced by having a long fluid flow path, a coiled, looped, curves, s-shaped, zigzagged fluid flow path and frequency attenuating lining material."

But whether this reaches production, or release, soon is anybody's guess.