Turn over your nearest gadget and there's an excellent chance you'll read “Made in China” on the casing. With labour cheap, resources close at hand, space costs at a minimum and the Chinese currency, the Yuan, kept low, it's not surprising that the world has turned to this powerhouse of Asia to manufacture its goods - something of which America is currently only too aware.

The city of Wuxi (pronounced Woo-She) in the east of the country is typical. Approximately 130km inland from the sprawling streets on steroids that are Shanghai, this flat-plained, purpose-built trade district is home to over 1,500 foreign enterprise operations. Serviced by its own freight airport a matter of minutes from the factory doors and China's second greatest architectural achievement, the Grand Canal, and with no geographical barriers to trouble its growth, it's the ultimate industrial estate. Not a huge surprise, then, that Japanese firm Nikon chose a Wuxi plant to mass produce its most ambitious project in recent times, the Nikon 1 interchangeable lens cameras.

Nikon Wuxi sits on a plot of land that covers over 97,000m² with a factory floor space just over half of that, and inside are masses and masses of China's most important resource - people. Each day, 130 commuter buses ship in an army of 8,292 of them to work one of two 8-hour shifts - day or night - with a civilised enough sounding hour-long lunch and 15 minute break here or there.

Two-lane corridors swarm with the troops each dressed identically, from the plant supervisor to the lowliest of grunts, in loose-fitting, beige safari suits complete with elasticated, transparent, blue, plastic slippers donned at the office door to keep even the tiniest of specs of dust from ruining the glassware and circuitry of the cameras. The only difference between them here or there are their orange, pink or blue hats denoting supervisor or managerial or novice roles from the otherwise baggy peaked caps worn by the overwhelming majority. Bright lights reflect in aluminium-framed work stations and the overhead silver ventilation hoses of the vast shop floors; the effect is something of a Bond villain's lair, only missing mock volcano wallpaper and a monorail.

Eighty per cent of the work force are women - both traditional and typical of factory work in China. They're walked through security at the beginning and end of each day to ensure that no recording devices come in and no sample parts go out. In an area of so much product manufacture and a land where the fakes and copies of the world largely originate, the measures are of little surprise.

Into the changing rooms, past the pigeon holes of rows and rows of identical, ceramic, stein-sized tea mugs - each with its owner's label in red - and the chatter and giggles of the corridors turn to silence the minute each is at their place in the production line, white surgical masks on. No talking, no music, their firm concentration is only punctuated by the sounds of an electronic clock chiming each quarter of an hour with a polyphonic version of Big Ben.

Wuxi is one of six Nikon factories in the world. Sendai and Tochigi in Japan manufacture professional grade DSLRs and the lenses for them. Nikon Thailand is where the consumer DSLRs are put together and the three plants in China are responsible for compacts. Wuxi makes lens units and is where the entire fabrication of the Nikon 1 cameras takes place.

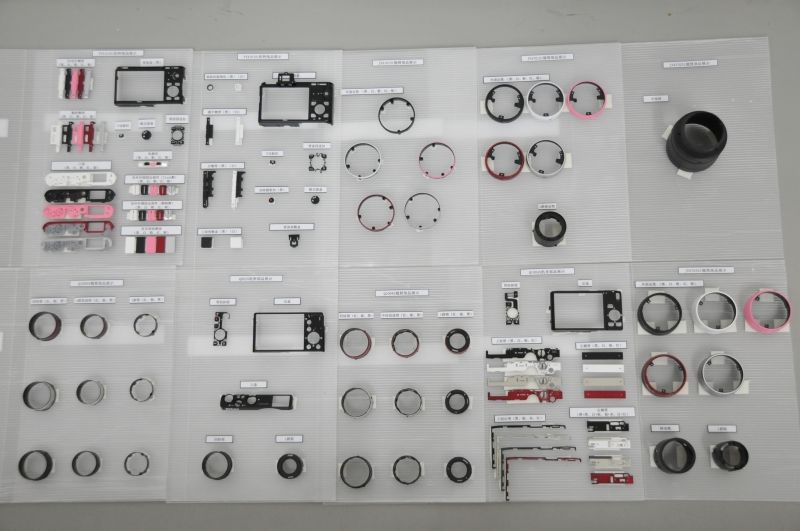

The J1 body consists of 182 parts each moulded, hand painted and assembled in separate sections of the factory, and when we say hand-painted, we mean it. There are workers whose job it is solely to write the white Nikon logo on each and every case with the finest of needle spray pens hooked up to tanks of indelible, oil-based inks. There are even those employed just to dot the shutter release with orange and others to place the single spec of white on the metal lens mount to indicate which way to put your lens glassware. Take a look at your camera now and you'll find a new appreciation of why it cost you a pretty penny.

The higher spec Nikon V1 totals 195 parts, but just as big a part of the operation is the manufacture of the Nikon 1 lenses themselves which take up a huge portion of the plant's resources in their own right. Like the bodies, the plastic of their housing is moulded and painted, but it's the glass that's of paramount importance with each penny-sized lens element passing through five stages of production before coming together in the bayonet units that photographers interchange as they need.

The glass is ground down by the workers with sanding machines on rough spinning mills flushed with water to wash away the shavings and grit. Next these diminutive discs are polished by rotating brushes and then coated by hand to protect the surfaces from damage. The fourth stage is where the elements are all put together :a worker cements and mounts each one on top of the next until the lens unit is in position and the final stage is to house the glass in the usable zoom-controlled attachments which we all take virtually for granted.

At the end of it all, each camera and lens is tested up against a swirling pattern of black and white on contrast sheets glued to the wall, before passing through quality control and packaged into boxes to be shipped off around the world.

It's a highly labour intensive process and one which you might expect to be mechanised elsewhere but, with such a huge work force in China, these feats are the most economic ways of getting the job done even if the sight of workers slumped asleep at the desks for their 15-minute breaks makes you wonder how wearing their occupation might be on the soul.

Although production has only just begun, the Nikon 1 camera project began in 2007 with the aim to create a "camera of best balance" according to the chief designer at Nikon Japan, Masahiro Suzuki. The company has made a conscious decision to concede high-end function for size and speed; the combination of a smaller sensor and powerful processor allowing for fast di-modal focusing over 135/73-points and a camera capable of shooting 30 images in half a second.

Should Nikon have hit it right, there are two more plots on the Wuxi site ready to be built upon which production could increase by 50 per cent on its own, as well as the option of a third 8-hour shift for round the clock activity. One thing for certain is that there'll be more than enough Chinese women to man it.